08 Dec Shop Local: The Urban Delivery Challenge

Ian Smith, Group Engineering Manager at Gray & Adams, shares his insight into solving the challenges of delivering in urban environments for its customers.

The Growth of Urban Deliveries

The decline of the traditional ‘big weekly shop’ has led to a huge rise in the practice of ‘topping up’ from more convenient, smaller, local retailers. The implication of this is that our customers now need to deliver higher volumes to their high street shops, whilst also reducing their journeys to cut carbon emissions. This paradox presents a number of tests for operators.

Top Challenges

- Maximising payloads

- Diminishing loads

- Turning circles

- Vulnerable road users

- Fuel efficiency

The most obvious challenge is the restriction to maximum vehicle size, due to manoeuvrability requirements. The available space within cities, means the height and width of vehicles need to be of a reduced size; this is something enforced by both operational feasibilities and law.

Sourcing smaller vehicles is a challenge that can be easily overcome. Sourcing smaller vehicles which deliver the large payloads required, however, is a bigger challenge. The test for delivering in urban environments is how to achieve large volume deliveries with a smaller vehicle.

This is not the only challenge, however. Most operators will run multi-drop deliveries, when stocking up inner city stores. This introduces the challenge of dealing with diminishing loads. When a load is reduced, the remaining stock can overload axles or kingpins, due to the increasingly unevenly distributed weight, which can cause terminal wear.

Gray & Adams’ engineering team must contend with the challenges of the tight turning circles required for manoeuvring and the increased measures required for protecting the high volumes of vulnerable road users in urban areas. Delivering in urban environments is a challenging operation, which requires specialist engineering.

Bespoke Solutions

Engineering at Gray & Adams involves designing the best product for the task, rather than delivering an off-the-shelf solution. Delivering in urban environments is one such challenge we help to resolve through tailored design and engineering.

Our sales team meet with customers to assess their requirements. We then begin the cross-department process of developing a specification. This process involves a clear analysis of what the customer needs, as well as the complexity of it. As part of this, our electrical, structural and mechanical engineers, along with our legal team, design team and management team, work to examine different areas of how this product could operate, looking to stress test solutions and confirm a feasible option. Only once each internal party has reviewed and signed off the final specification, is the product presented to the customer and then signed off for production.

This problem-solving process allows us to collectively engineer solutions which resolve the challenges that urban operators face. For example, to allow the delivery of large volumes with a small vehicle we look to utilise variations of double-deck units. This enables us to maximise payload, whilst maintaining a smaller size. To allow for the tight turning circles required, we design bespoke systems, validated by computer simulations to ensure acute angles of manoeuvrability can be achieved, where required, in support of our customers delivery objectives.

Our customer says

“Having worked with Gray & Adams for 26 years, we have first-hand experience of their track record in providing engineering solutions which allow us to overcome the many challenges of delivering in urban environments. We have engaged with Gray & Adams on a number of key projects for James Hall & Co over the years, and their innovative and high-quality solutions have now become part of our standard specification.

The longevity of our relationship shows the strength of our partnership and exemplifies the trust we place in Gray & Adams to keep delivering for us. The speed of reaction to technical enquiries and access to key personnel within their organisation is pivotal when deciding which suppliers we work with, given the ever changing sector that we operate in. This enables us to make key decisions with confidence.

We are currently working on some further engineering innovation from Ian Smith and his team in the urban delivery space, which will hopefully be completed in the coming months.”

– Ian Farnworth, Fleet Engineering Manager, James Hall & Co Ltd.

Latest News

-

Retirement Spotlight | Brian Wood

Gray & Adams said goodbye to long-serving employee Brian Wood who worked for the company for the last 13 years....

-

Retirement Spotlight | William Clark

Gray & Adams said goodbye to long-serving employee William Clark who worked for the company for the last 50 years....

-

Staff Spotlight | James Hendry

In this staff spotlight, we catch up with James Hendry, who looks after the on-site first aid facility and team of first aiders....

-

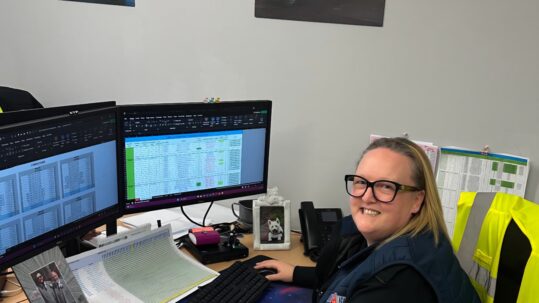

Staff Spotlight | Carrie Bennett

In this edition of our Staff Spotlight, we catch up with Carrie Bennett, who joined Gray & Adams in January 2024....

-

Retirement Spotlight | Jim Duncan

Gray & Adams said goodbye to long-serving employee Jim Duncan who worked for the company for the last 20 years....

-

Retirement Spotlight | Brian Allan

Gray & Adams said goodbye to long-serving employee Brian Allan who worked for the company for the last 38 years....